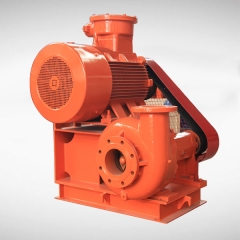

Vertical cutting dryer is used to do further separation for cuttings to recover valuable drilling fluids, drying solids discharge, cleaning return fluid, reducing mud loss. Cuttings discharged by shale shaker, desander, desilters (or mud cleaner) can be fed into the dryer’s hopper and spaced widely to the inner screens, achieving the drying and separating efficiency.

Brightway BWLS1600 Vertical Cutting Dryer Advantages: Professional high - performance motor, faster speed, strong processing capacity and Long life. According to the different environmental and industrial requirements of customers, Brightway can product different kinds Drying Centrifuges adapt to different mud performance.

Brightway Vertical Cutting Dryer Advantages

1. Adopting Italy comprehensive analysis technology to meet domestic and overseas customers `s treatment requirments on the drilling site.

2.The Capacity can be up to 50 tons.

3. It can separate and dry different kinds of drilling waste, such as water-based mud, oil-based mud, composite mud.

4. Adopting independent oil lubrication and cooling system to extend equipments lifetime.

5.The discharge port is flexible to operate, which can be in different types, such as spiral type, belt type.

6. Water-based mud and composite mud: Water content 8-10%, oil-based mud: water content≤6%, OOC≤3%.

Brightway Vertical Cutting Dryer Parameters

| Model | BWLS1600 | BWLS800 |

|---|---|---|

| Capacity | 40-50 T/h | 25-30 T/h |

| RPM | 0-900 r/min or 900r/min | 0-1100 r/min or 1100r/min |

| G-Force | 420G | 390G |

| Gap Size | ≥0.2mm | ≥0.2mm |

| Noice level | ≤85dB | ≤85dB |

| Dimension (mm) | 2855 ×2150 ×2050 mm | 2250 ×1600 ×2050 mm |

| Weight (kg) | 6000 kg | 2900 kg |

| Power | 220-240V/ 50Hz, 380-415V/ 50Hz, 440-480V/ 60Hz, 575-600V/ 60Hz | |

| Approval | IEC/UL/ATEX/CE | |

Remark

1. Motor and bearing can be selected according to customer requirements, non-explosion-proof and explosion-proof can be selected according to the use industry;

2. The gap size of sieve basket can be determined according to the treatment medium;

3. The way of discharging port can be decided according to the field requirements;