Products

- Solids Control Equipment

- Triple Deck Shale Shaker

- Shale Shaker

- Vacuum Degasser

- Mud Cleaner

- Desander

- Desilter

- Decanting Centrifuge

- Sludge Vacuum Pump

- Vertical Cutting Dryer

- Drying Shale Shaker

- Jet Mud Mixer

- Mud Agitator

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Gun

- Mud Gas Separator

- Fire ignition device

- Screw Pump

- Hydration Tank

- Mud Tank

- Elevated Oil Tank

- Diesel Tank/Oil Tank

- Motor Control Center Room

- Screw Conveyor

- Offshore Mud Skip Container

- Solids Control System

- Spare Parts

- Drilling Rig

Contact

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Cases

-

3000hp Drilling Rig Circulation System for 9000m U...

3000hp Drilling Rig Circulation System for 9000m Ultra Deep Drilling Proj...

-

2000hp Drilling Rig Mud Tank System for Saudi Arab...

2000hp Drilling Rig Mud Tank System for Saudi Arabia As earl...

Slurry Separation Plant

Slurry Separation Plant

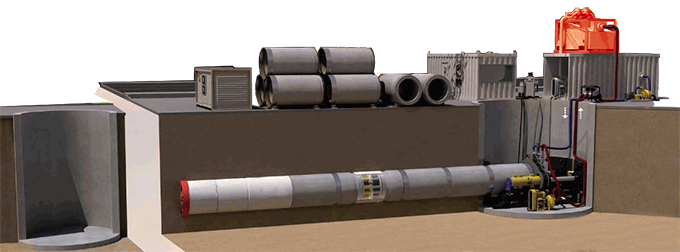

⇒ Typical Slurry Separation Plant Job Site

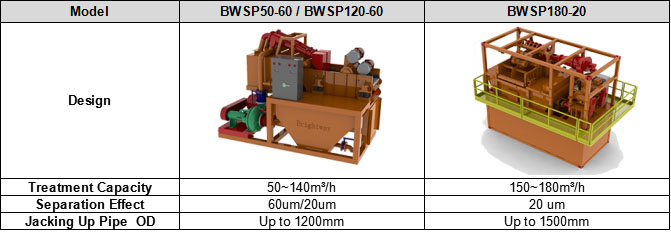

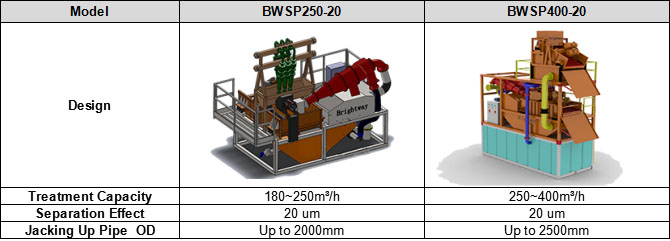

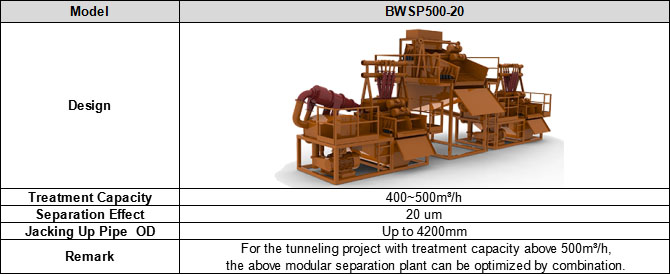

⇒ Brightway Slurry Separation Plant Parameters

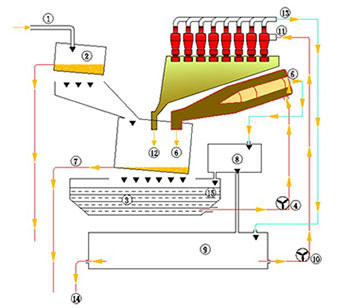

⇒ Slurry Separation Plant Separation Process

• Slurry charged with soil is conveyed to the plant through the supply line (1) and let out onto a vibrating coarse sieve (2) which removes particles exceeding 5 mm in size.

• Slurry charged with soil is conveyed to the plant through the supply line (1) and let out onto a vibrating coarse sieve (2) which removes particles exceeding 5 mm in size. • The sieved slurry processed by the second fine shaker and drops into a trough and passes through a pipe into the main reservoir (3) of the desanding module from where it is pumped (4) to the two main cyclones (5) which separate out sand from the slurry.

• The sand pours out through the underflow outlets (6) of the cyclones and drops onto a vibrating fine sieve to be dewatered and removed (7) from the process.

• The treated slurry leaving the cyclones through the overflow outlets pours into an intermediate tank (8) from where it passes to a storage tank (9).

• A further refinement of the slurry can be achieved by pumping (10) already.

⇒ Brightway Slurry Separation Plant Features

2. Stable and bobust separation process;

3. Easy setup amd operation;

4. Capable of handling high solids loads;

5. Field-proven screen system-durable and adjustable;

6. Powerful G-forces with double-deck shakers;

7. Well-designed cyclones for a better fine-cut even under difficult conditions;

8. Wear resistant pumps;

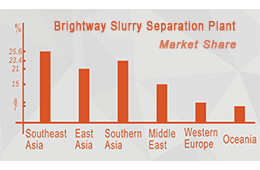

⇒ Brightway Slurry Separation Plant Cases

BWSP120-60

BWSP120-60 Job Site: Singapore

Capacity: 120m³/h

BWSP180-20

BWSP180-20Job Site: Doha

Capacity: 180m³/h

BWSP250-20

BWSP250-20Job Site: Malaysia

Capacity: 250m³/h