Desander is made to make sure sand is completely isolated from drilling fliuds. It is made to make sure sand is completely isolated from drilling fliuds. Brightway desander has been optimizing processed to match the modern drilling system demands.

Brightway BWCSQ Series Desander Advantages

1. Our desander is produced on the basic of clients' demands.

2. Brightway desander is easy to operate, and all of the spare parts can be interchangeable with world famous brand.

3. Brightway desander is designed in ANSYS finite element analysis, and our design has been optimized to meet ergonomic operation maximum.

4. We adopt pickling, passivation, and hot galvanizing technology which greatly improves the working time of the desander.

5. Brightway desander is deployed with Oli Vibration motor.

6. We select Siemens, Schneider, ABB and other international well-known electrical components for Brightway desander.

7. We select high wear resistant composite polyurethane material for cyclone, which can be interchangeable with international brands.

Brightway BWCSQ Series Desander Parameters

| Model | BWCSQ 250-2S | BWZJ 101-2S | BWCSQ 250-1S | BWZJ 101-1S |

|---|---|---|---|---|

| Capacity | ≤240m3/h (1056GPM) | ≤120m3/h(528GPM) | ||

| D-SANDER Cyclones | 2×10″ (250mm) | 1×10″ (250mm) | ||

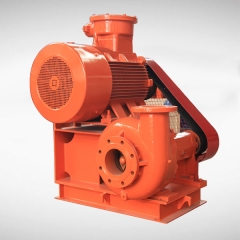

| Matching Pump | 55kw (73hp) | 30kw (40hp) | ||

| Motors Output | 0.4 kw (0.53hp) ×1(OLI) | 0.45kw (0.6hp) ×2(OLI) | 0.4 kw (0.53hp) ×1(OLI) | 0.45kw (0.6hp) ×2(OLI) |

| G-Force | ≦6.5 Gs | ≦7.0 Gs | ≦6.5 Gs | ≦7.0 Gs |

| Motion Trail | Circular vibration type | linear type | Circular vibration type | linear type |

| Screen Size | 600X1600 mm | 585×1165 mm | 600X1600 mm | 585×1165 mm |

| Screen Qty | 1pc | 1pc | 1pc | 1pc |

| Screen Area | 1 ㎡ (11ft²) | 0.70㎡ (7.8ft²) | 1 ㎡ (11ft²) | 0.70㎡ (7.8ft²) |

| Screen Mesh | API 120 /150 /175 | |||

| Weight (kg) | 780 | 950 | 750 | 750 |

| Dimension (mm) | 1465 x1510 x2390 | 1450 x1390 x2320 | 1465 x1510 x2390 | 1465 x1510 x2390 |

Remark

1. Equipment Certification: IEC/UL/ATEX/CE;

2. Power Selection: 220-240V/50Hz, 380-415V/50Hz, 440-480V/60Hz, 575-600V/60Hz;

3. Environmental temperature: 30 ° C (86 ° F); Design range: -40-50 ° C (-40-122 ° F); Noise control: 75-85 dBA;

4. Shaker motor type selection can be configured according to customer requirements, explosion-proof and non-explosion-proof can be selected according to industry requirements;

5. The matching shaker and cyclone can be selected according to the purchasing power of customers;

6. Shaker screen can be selected according to customer requirements, iron frame, composite material or plate wave screen;

7. The treatment capacity of the above equipment is measured in mud density: 1.2g /cm3, mud viscosity :45s, screen mesh: 40 mesh;