Products

- Solids Control Equipment

- Triple Deck Shale Shaker

- Shale Shaker

- Vacuum Degasser

- Mud Cleaner

- Desander

- Desilter

- Decanting Centrifuge

- Sludge Vacuum Pump

- Vertical Cutting Dryer

- Drying Shale Shaker

- Jet Mud Mixer

- Mud Agitator

- Centrifugal Pump

- Shear Pump

- Submersible Slurry Pump

- Mud Gun

- Mud Gas Separator

- Fire ignition device

- Screw Pump

- Hydration Tank

- Mud Tank

- Motor Control Center Room

- Screw Conveyor

- Offshore Mud Skip Container

- Barite Bulk Silo

- Solids Control System

- Spare Parts

Contact

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China

Room 11608, Unit 1, Building C, Door of Metropolis, Tangyan South Road, New Area of High-tech District, Xi'an City, Shaanxi Province, China  +86-29-89305761

+86-29-89305761 +86-29-89305769

+86-29-89305769

Cases

-

ZJ50LDB Solids Control System in Russia

ZJ50LDB Solids Control System for Italy Hydraulic Drilling Rig in Russia ZJ50LDB...

-

350 GPM Mud Recycling System in Thailand

350 GPM Mud Recycling System in Thailand This 350GPM Mud recovery system is comp...

Technology News

Desander and Desilter Hydroyclones in Oil and Gas Drilling

2022-03-09

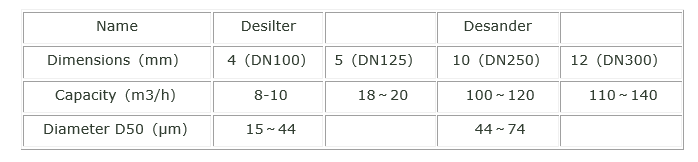

Desander and desilter are the second and third-stage desanding and desilting equipment in mud purification equipment. They process the smaller particle solid phase.

Both the desander and desilter consist of a set of hydrocyclones and a small ultra-fine mesh screen that treats the underflow of the cyclone and recovers drilling fluid. Desander is used to remove 44-74μm solid phase particles, and desilter is used to remove l5-44μm solid phase particles. The particle size D50 in the cyclone is not only related to the structure size of the cyclone, but also related to the drilling fluid concentration, density and fluid inlet pressure.

In order to meet the requirements of processing all drilling fluids, the desander and desilter must be composed of several swirl cones. In order to ensure the normal operation of the cyclone, the liquid inlet pressure must be maintained within the range of 0.25-0.35MPa. Because the desilter has many swirl cones and long pipelines, the liquid inlet pressure should take a larger value; because the desander has fewer swirl cones and short pipelines, the liquid inlet pressure should take a smaller value. The size of the liquid inlet pressure mainly depends on whether the matching of the sand pump is reasonable, so the selection of the sand pump is very important. equal to meet the usage requirements.

At the same time, the maximum displacement of the drilling pump must be referred to when selecting the desander and desilter, in order to achieve a reasonable matching. There is no strict limit on the use time of these two types of equipment. Generally, when drilling shallow formations and soft formations, the content of large-particle cuttings in the drilling fluid is high, and the two must be used at the same time; when drilling formations and hard formations, if using fine mesh shale shaker can directly use the desilter to treat the drilling fluid, which has little effect on the purification quality of the drilling fluid and is very economical.

Previous :High G-Force Cuttings Dryer for OBM Drilling Waste Working